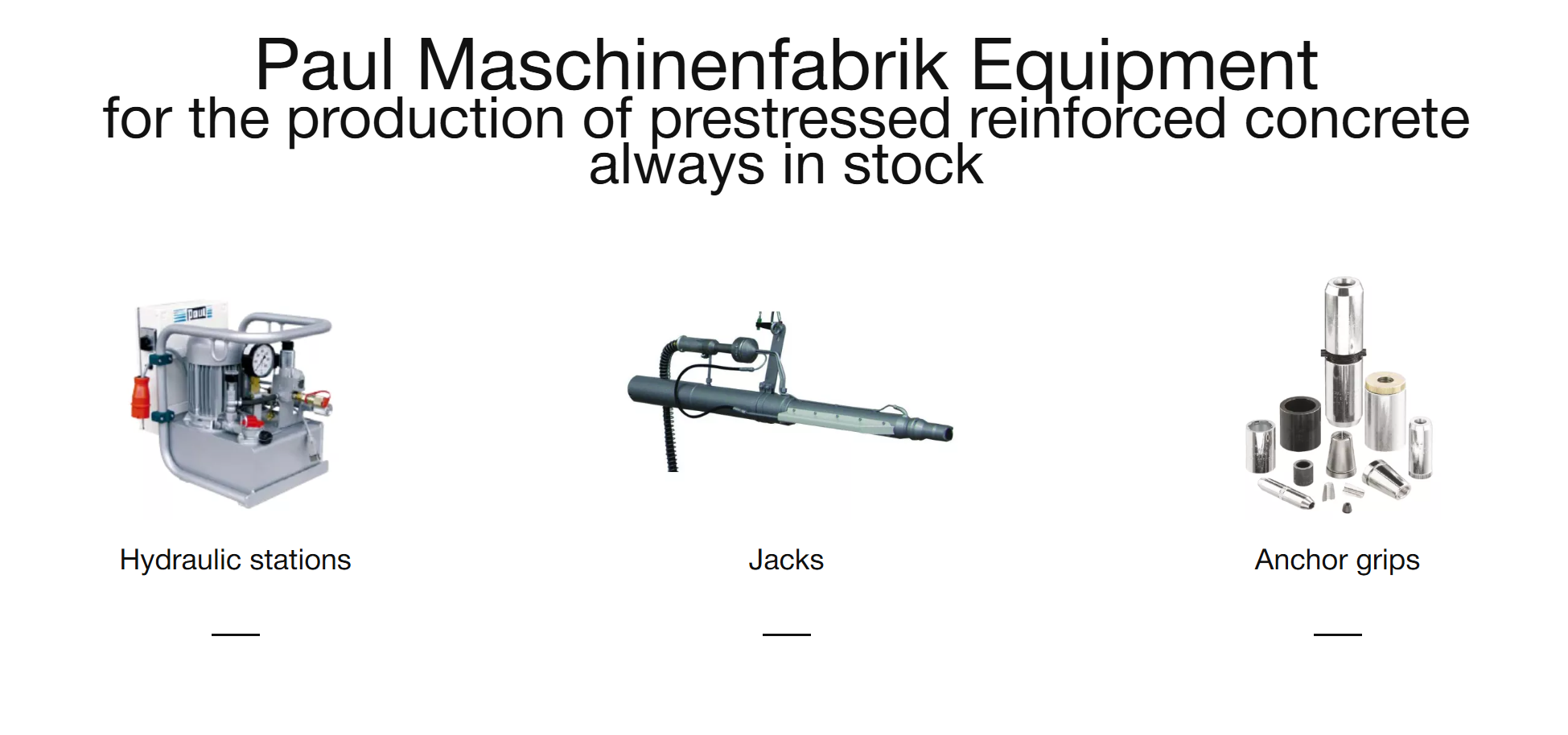

PAUL's steel rebar, wire and strand tensioning equipment is well known for its reliability and high quality, making it indispensable in reinforced concrete (RC) plants and on construction sites. This comprehensive set of equipment is designed to work with prestressed reinforced concrete, which is used to create durable and strong structures. PAUL's products, including hydraulic stations, jacks and anchor grippers, facilitate the efficient tensioning of reinforcement, which is an important part of prestressed concrete technology.

PAUL hydraulic stations

PAUL hydraulic stations provide uninterrupted power to jacks and other tools used in the tensioning of steel reinforcement, wire and strands. These stations are characterized by high power and reliability, which allows them to be used even in harsh industrial environments. PAUL hydraulic stations offer the following advantages:

- Mobility - they can be used both in the factory and on construction sites, moving them between work areas.

- High performance - the stations work efficiently and reliably, providing a constant pressure supply for jacking operations.

- Resistant to loads - PAUL hydraulic stations are designed to last for long periods of time, even under heavy loads, which is important for large projects.

PAUL valve tensioning jacks

Jacks are a key element of the rebar tensioning system. PAUL jacks are designed to handle a variety of rebar types, including steel bars, wire and stranded steel strands. They allow precise tension control to ensure the quality of prestressed structures. Features of PAUL jacks:

1. Variability in tensioning force - the force can be adjusted to meet the requirements of a particular project.

2. Multifunctionality - the jacks can tension several reinforcement bars simultaneously, which speeds up the process and increases productivity.

3. Robust and reliable - the jacks are made of high quality materials and are designed to withstand many years of heavy use.

PAUL anchor clamps

PAUL anchor clamps play a key role in the prestressing process by securing the reinforcement after tensioning. PAUL produces several types of anchor clamps for different structures and operating conditions:

- Open Type “A” - used on the active side of tensioning.

- Closed Type “F” - used on the passive side.

- Coupling Type “K” - used to connect individual sections of rebar, allowing for longer lengths of tension structures and larger scale applications.

These anchor clamps act as a secure anchorage, which prevents the tension from loosening over time and ensures the longevity of the prestressed structure.

Advantages of PAUL rebar tensioning equipment

PAUL equipment solves a number of key challenges in the prestressed concrete production process by providing reliable and durable rebar tensioning. Here are the main advantages of this equipment:

1. High precision - PAUL equipment provides precise control of rebar tensioning, which is critical to the quality of the final product.

2. Versatility and adaptability - thanks to their versatility, the devices can be used at different stages and in different types of construction.

3. Time saving - the possibility of simultaneous tensioning of several reinforcement bars reduces the time required to complete tasks.

4. Durability - the equipment is made of high quality materials, which guarantees its reliable operation for many years, even under intensive use.

PAUL rebar tensioning equipment is a complete and reliable solution for prestressed concrete production. Its hydraulic stations, jacks and anchor clamps optimize the production process, increasing the quality and durability of the finished structures. Reliability, adaptability and cost-effectiveness make PAUL equipment one of the best solutions for efficient rebar tensioning, helping to realize projects of any complexity and scale.